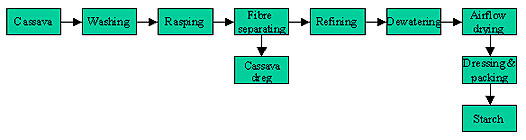

Cassava starch production process is a process of dissociating cassava starch from cellulose, protein, inorganic and other material, it is physical separation process. On the basis of that starch does not dissolve in cold water and it is much denser than water, make use of water and cassava starch machinery, during the production process, separate the starch from water in the suspension, so as to achieve the purpose of recycling starch. In order to reach to purposes of removing mud and cleaning the raw materials, mixing washing process uses paddle mixer and u-shaped slot injected with water, integrated the rabbling, friction, kneading, throwing, bump and several kinds of cleaning method. After washing process the raw material is feed into the roller. Raw material rolls forward with rotating drum wall to water spray, washing, friction, cleaning, to further shelling. Raw material is feed into the broken process to complete the cassava crushing and the separation of starch paste and potato slag after further cleaning.

Starch whey will be pumped in sand removing machine by pressure pump according to the principle of specific gravity separation, bottom flow removes sand, top flow slurry, remove the fine sand in starch paste so as to further improve the precision of starch. On the basis of the different dense of water, starch and yellow plasma protein, dissociate starch whey from insoluble protein and the remnants of soluble protein and other impurities, so as to achieve the purpose of washing, refined and concentrate the starch. Dehydrate the starch that after refining and concentrating adopts vacuum filter principle to achieve the required water content (about 40%), also can use scraper centrifuge instead. Wet material feed into the dry powder tube from feeding machine, fresh air will be feed into the tube and mix with grain mill after heated by radiator, because of the fan dynamic function wet material will suspended in heat flow and get dry for the heat exchange.

Then we get helpful cassava starch and can use it in most aspects of life.Adopted wet processing technology of Cassava milling equipment, cassava starch process does not add any additives, the whole process uses mature technique, advanced equipment, scientific configuration and reasonable technology. The process of cassava starch process is well designed in the light of cleaning-broken-sieving-refine-dehydration-dried six sections. The broken and sieving section of cassava starch process possesses advantages of low energy consumption, high starch extraction yield, good starch quality, improve the production efficiency and starch extraction yield of production line through the unique craft of multistage crush, multistage filters, multistage squeezing of circulation.

没有评论:

发表评论