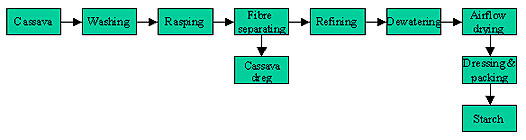

Cassava starch production process is a process of dissociating cassava starch from cellulose, protein, inorganic and other material, it is physical separation process. On the basis of that starch does not dissolve in cold water and it is much denser than water, make use of water and cassava starch machinery, during the production process, separate the starch from water in the suspension, so as to achieve the purpose of recycling starch. In order to reach to purposes of removing mud and cleaning the raw materials, mixing washing process uses paddle mixer and u-shaped slot injected with water, integrated the rabbling, friction, kneading, throwing, bump and several kinds of cleaning method. After washing process the raw material is feed into the roller. Raw material rolls forward with rotating drum wall to water spray, washing, friction, cleaning, to further shelling. Raw material is feed into the broken process to complete the cassava crushing and the separation of starch paste and potato slag after further cleaning.

2012年3月13日星期二

Cassava Milling Equipment

Being as perennial shrubs, the root of cassava is cylindrical, with different breeds, its root number and size varies greatly. Cassava root is rich in starch, and its protein, grease and ash content are rarely, fresh cassava root starch content is 25%-32%. This shows that cassava is a good starch raw material. Cassava starch is widely used in food industry and other industry, it is a powder that extracted from cassava and dehydrated.

Cassava starch production process is a process of dissociating cassava starch from cellulose, protein, inorganic and other material, it is physical separation process. On the basis of that starch does not dissolve in cold water and it is much denser than water, make use of water and cassava starch machinery, during the production process, separate the starch from water in the suspension, so as to achieve the purpose of recycling starch. In order to reach to purposes of removing mud and cleaning the raw materials, mixing washing process uses paddle mixer and u-shaped slot injected with water, integrated the rabbling, friction, kneading, throwing, bump and several kinds of cleaning method. After washing process the raw material is feed into the roller. Raw material rolls forward with rotating drum wall to water spray, washing, friction, cleaning, to further shelling. Raw material is feed into the broken process to complete the cassava crushing and the separation of starch paste and potato slag after further cleaning.

Cassava starch production process is a process of dissociating cassava starch from cellulose, protein, inorganic and other material, it is physical separation process. On the basis of that starch does not dissolve in cold water and it is much denser than water, make use of water and cassava starch machinery, during the production process, separate the starch from water in the suspension, so as to achieve the purpose of recycling starch. In order to reach to purposes of removing mud and cleaning the raw materials, mixing washing process uses paddle mixer and u-shaped slot injected with water, integrated the rabbling, friction, kneading, throwing, bump and several kinds of cleaning method. After washing process the raw material is feed into the roller. Raw material rolls forward with rotating drum wall to water spray, washing, friction, cleaning, to further shelling. Raw material is feed into the broken process to complete the cassava crushing and the separation of starch paste and potato slag after further cleaning.

2012年3月11日星期日

Wheat Flour

The type of flour is developing rapidly nowadays. Now the flour is sorted mare and more meticulous, there are even more than 10 kinds of flour, common wheat flour is as follows. Special high gluten flour is usually used to make gluten, and fried dough sticks, its moisture is 14%, crude protein more than 13.5%. Bread flour with moisture of 14%, crude protein more than 11.5%, the protein content of bread flour is in an average of 13.5%, and usually the protein content in 11.5% or more can be called as bread flour. Protein content is high and gluten is more, accordingly it is more used to make bread, noodles and so on.

Plain flour is usually used to make Chinese snacks like steamed bread, steamed buns, western cookies, its moisture is 13.8%, crude protein more than 8.5%. All purpose flour is generally used to make steamed stuffed bun, steamed buns, dumplings and pancakes. The flour in the common menu that is not specifically noted is this type of small grain mill. Baking flour is usually used to make cake, cookies, small cake desserts, its moisture is 13.8%, crude protein below 8.5%. It is suitable for almost all kinds of cakes, biscuits, crisp skin kind of dessert.

Domestic call baking flour as cake powder or pastry powder, protein content of 8%-9%, the main production is cake, for cake cannot be pliable but soft. Do choose baking flour to make sponge cake, and choose cake all purpose flour to make grease cake, for baking flour is not stretchy, cake made of it is special soft, the volume is swollen, and the surface is flat. Grease cake structure itself is loose than sponge cake, choose all purpose flour to make the structure further intensive, thus become more closely and dense.

Cake flour is suitable for making cake, cookies and other snacks, we can mix four parts all purpose flour plus one part corn starch to obtain cake flour. All purpose flour domestic called as refined powder, the most common flour, protein content of 9.5-11.5%, used for steamed bread, steamed stuffed bun, dumplings, pancakes, noodles, most Chinese style snacks. Bread flour is the most pliable flour for its protein content is above 11.5%, used for making snacks that need to rely on strong elasticity and ductility to parcel air bubbles, so that the loose structure is formed.

As you know, all types of wheat flour are made by wheat flour mills machine no matter it is suitable for what kind of food. Flour milling machine is a kind of machinery which contains motive power, feeding, grinding and separation system components. The structure is simple, processing and installation technology is good, volume is small, noise is low, convenient operation, is not easy to produce a torque or bond flour. There are many things need to be taken into account if you are considering of buying a flour milling machine of good quality.

Domestic call baking flour as cake powder or pastry powder, protein content of 8%-9%, the main production is cake, for cake cannot be pliable but soft. Do choose baking flour to make sponge cake, and choose cake all purpose flour to make grease cake, for baking flour is not stretchy, cake made of it is special soft, the volume is swollen, and the surface is flat. Grease cake structure itself is loose than sponge cake, choose all purpose flour to make the structure further intensive, thus become more closely and dense.

Cake flour is suitable for making cake, cookies and other snacks, we can mix four parts all purpose flour plus one part corn starch to obtain cake flour. All purpose flour domestic called as refined powder, the most common flour, protein content of 9.5-11.5%, used for steamed bread, steamed stuffed bun, dumplings, pancakes, noodles, most Chinese style snacks. Bread flour is the most pliable flour for its protein content is above 11.5%, used for making snacks that need to rely on strong elasticity and ductility to parcel air bubbles, so that the loose structure is formed.

As you know, all types of wheat flour are made by wheat flour mills machine no matter it is suitable for what kind of food. Flour milling machine is a kind of machinery which contains motive power, feeding, grinding and separation system components. The structure is simple, processing and installation technology is good, volume is small, noise is low, convenient operation, is not easy to produce a torque or bond flour. There are many things need to be taken into account if you are considering of buying a flour milling machine of good quality.

2012年3月5日星期一

Cassava Processing Machine

First the new harvest cassava will be stored in processing plant in clean concrete in the bunker. From there cassava will be carried by belt conveyor to the cleaning rotating drum. After cleaning the cassava is sent to the cleaning/peeling machine, and in cleaning/peeling machine with clean water to make up for the loss and sewage. Water comes out of the cleaning/peeling machine flows through a rotating sieve to remove potato skins and rough grain, and then pump into a hydrocyclone desander to remove the sand cassava brings.

After purification the water is pumped into the cleaning/peeling machine. The rotating sieve will expel the isolated cassava skins and other fiber. Cassava will be transported to a check belt conveyor to check the stone stocked in cassava or the damage caused by the parasite when comes out of cleaning/peeling machine, this machine will cut them into pieces. Because the cutting machine is located above the feed hopper of the flour grinding machine, the cassava pieces will be collected in the hopper. Cassava pieces will be feed into the milling machine from the hopper by a spiral whose speed is adjustable.

Shredded cassava pieces are feed into the cassava flour milling machine. Feed screw conveyor and hopper are connected to the bottom. The production of production line is controlled by feeding conveyor. When comes out from the grinding machine, crude cassava starch will moves into sand eliminating unit to the removal of emulsion sand and other coarse particles. The crude starch emulsion was sent to extract unit after sand eliminating. Crude starch is feed into nozzle separator emulsion through a precise sift. Crude starch is concentrated emulsion will be continuously discharged from the nozzle.

At the same time the cleaning water will be feed in the nozzle, because the concentration and cleaning are combined, and the combination of most of the impurities such as protein, latex and other from starch soluble substance of separation of overflow way to leave separator. Concentrated cassava starch after emulsion will be feeding directly into washing purification unit by a slurry pump. Washing purification unit is a multi-stage hydrocyclone unit, including washing purification and recycling. Starch is counter current rinse, protein content will be reduced to the required levels and remove fine fiber and other impurities.

The overflow of the part from washing flows into the recovery of recycling the remnants of starch. The isolated fiber is pumped into fiber dehydration unit for further dehydration. The starch percolate is recycled by a rotary flow unit and feed into the recovery of starch collecting cans. After starch emulsion mechanical dehydration, starch blocks are sent to the air dryer entry to dry into commodities level national starch by belt conveyor. Wet starch will be sent to the product feed hopper, and from there move into dry the heat flow in the pipeline. Starch is heat flow heating, water evaporated. After drying, starch through a set of cyclone separator and air separation.

After purification the water is pumped into the cleaning/peeling machine. The rotating sieve will expel the isolated cassava skins and other fiber. Cassava will be transported to a check belt conveyor to check the stone stocked in cassava or the damage caused by the parasite when comes out of cleaning/peeling machine, this machine will cut them into pieces. Because the cutting machine is located above the feed hopper of the flour grinding machine, the cassava pieces will be collected in the hopper. Cassava pieces will be feed into the milling machine from the hopper by a spiral whose speed is adjustable.

Shredded cassava pieces are feed into the cassava flour milling machine. Feed screw conveyor and hopper are connected to the bottom. The production of production line is controlled by feeding conveyor. When comes out from the grinding machine, crude cassava starch will moves into sand eliminating unit to the removal of emulsion sand and other coarse particles. The crude starch emulsion was sent to extract unit after sand eliminating. Crude starch is feed into nozzle separator emulsion through a precise sift. Crude starch is concentrated emulsion will be continuously discharged from the nozzle.

At the same time the cleaning water will be feed in the nozzle, because the concentration and cleaning are combined, and the combination of most of the impurities such as protein, latex and other from starch soluble substance of separation of overflow way to leave separator. Concentrated cassava starch after emulsion will be feeding directly into washing purification unit by a slurry pump. Washing purification unit is a multi-stage hydrocyclone unit, including washing purification and recycling. Starch is counter current rinse, protein content will be reduced to the required levels and remove fine fiber and other impurities.

The overflow of the part from washing flows into the recovery of recycling the remnants of starch. The isolated fiber is pumped into fiber dehydration unit for further dehydration. The starch percolate is recycled by a rotary flow unit and feed into the recovery of starch collecting cans. After starch emulsion mechanical dehydration, starch blocks are sent to the air dryer entry to dry into commodities level national starch by belt conveyor. Wet starch will be sent to the product feed hopper, and from there move into dry the heat flow in the pipeline. Starch is heat flow heating, water evaporated. After drying, starch through a set of cyclone separator and air separation.

订阅:

博文 (Atom)